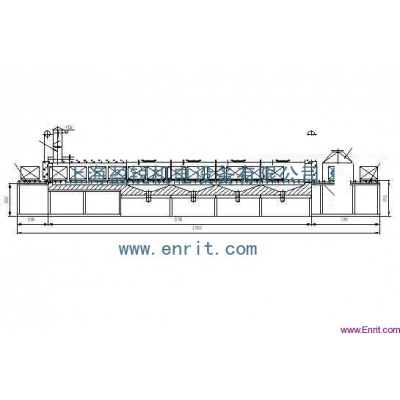

burning sand Furnace

Uses:

Kawasaki is mainly used for automobile air intake pipe, head of the burning sand treatment process

Structure description:

Continuous combustion of natural gas burning sand roll transfer device that includes a feeding station, warm room, sand burning stove, door and door elevator, air-cooled discharge chamber, discharge units, combustion systems, roller transmission system, exhaust system, discharge units, electronic control system components.

Features:

1, the burning hot sand spilled directly into the oven preheating chamber, preheating the workpiece first, and then enter the burning sand furnace, heating the workpiece to save time, but also saves energy;

2, combustion installations peroxide combustion, excess air generated by the oxidation of the atmosphere gas in the furnace for air circulation, so that the sand mold of the binder is burned, the sand can be quickly scattered.

3, roller transfer process, set the process in its forward movement in reverse mixed interpolation. This action can prevent the roller deformation, can play a jitter baskets make the internal parts within the sand mold off;

4, burning furnace bottom with sand sand sand bucket and a mouth, easy to sand;

5 burner stove top in the burning sand staggered arrangement on both sides of the location; good temperature uniformity;

6, the workpiece burning sand process was completed, into the air chamber, cooling rapidly, as the work piece into the next process as soon as possible to save time.