Shanhai Enrit Mechanical & Electrical Equipment Co., Ltd. With 20 years experience in the design of industrial furnaces, with superior technique overall responsibility for heat treatment equipment to provide customers with engineering solutions, for a reasonable process validation, improved technical support, technology transfer and a full set of detailed technical training to ensure that customers complete design projects successfully completed. Also granted the overall responsibility to the customer is responsible for technology licensing and related accessories to customers.

We can provide comprehensive services in the following areas:

1) The scope of industrial furnace design:

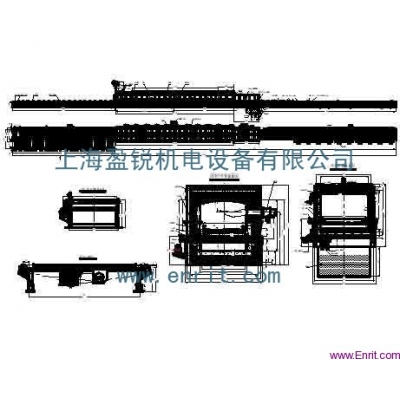

Furnace Type: Aluminium Melting Furnace、Annealing Furnace�、Batch Type Forging Furnaces����、Bell Furnace、Bogie Hearth Furnace��、Box Furnace、Brazing Furnaces���、Car Bottom Furnace���、Carburizing Furnace��、Continues Brazing Furnaces、Continues Mesh Belt Furnace with Endogas Atmosphere���、Continuous Heat Treatment Furnace、Crucible Furnace�、Electric Furnaces���、Electrical Auto Quench Furnace���、Electrically Heated Furnace���、Forge Furnace���、Gas Carburizing Furnace�、Gas Furnaces����、Gas Powered Furnace�、Gas/Oil Fixed Auto Quench Furnace、Induction Furnace����、Induction Melting Furnace、Industrial Batch Furnace���、Industrial Continuous Furnace、Industrial Furnace���、Laboratory Furnace、Lead Refining Furnace����、Muffle Furnace、Multiple Hearth Furnace�����、Oil Furnaces�、Oil, Gas & Electrical Bogie moving Furnace��、Oil, Gas & Electroical Furnace moving����、Pellet Furnaces 、Pit Furnace����、Propane Furnaces ���、Radiant Tube Furnace、Reverberatory Furnace����、Rotary Furnace��、Rotary Helth Furnace����、Salt Bath Furnace��、Shaker Hearth Furnace、Sintering Furnaces�、Tilting Barrel Metal Furnace���、Tube Furnace���、Vertical Furnace����、Welding Oven Furnace;

Delivery method: mesh belt furnace (bridge, and the atmosphere protection), chain belt furnaces, roller hearth furnace, putting furnace;

Non-ferrous metal heat treatment equipment (solid melting, aging, quenching, annealing); ferrous metal heat treatment equipment (quenching, tempering, annealing, quenching, normalizing, ball annealing, carburizing, nitriding, carbonitriding, multi-purpose furnace )

Companies are particularly good at non-standard industrial furnace (the heat source is electricity, gas, oil) design.

2) The design features of the industrial furnaces:

The layout design of industrial furnaces, compact;

Industrial furnace design is simple, easy maintenance;

Modeling of industrial furnace design is reasonable, novel, small footprint;

Design of industrial furnaces can be comparable with foreign same device.

3) The design drawings to ensure the quality:

Our design drawings, design drawings from the programming to be completed, the entire process is carefully designed, carefully proofread, strict examination, and checking. According to quality, quantity and time to complete the design task.

We always strive to promote the development Heat Treatment Engineering, to ensure products meet the technical requirements based on the cost of the equipment in the design of lower to a minimum. Therefore, we believe we will be your best partners in the field of heat treatment equipment .