| PURPOSE |

1)�����、Applicable to solution heat treatment, quenching and aging continuous treatment for aluminum alloy wheels

2)�、Used for sand-burning treatment for aluminum alloy automobile engine cylinder head |

| STRUCTURE DESCRIPTION |

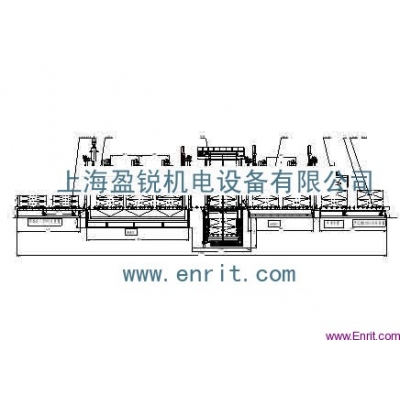

The furnace body adopts top hot air circulating direct-fired heating method, the discharged waste gas can be re-used via heat exchanger, and lightweight heat insulation cotton with small heat storage capacity is selected for refractory material, hearth roll gap-type operating mode is adopted for transmission, heating element is the burner(the fuel is natural gas or liquefied gas) and opposite-shooting infrared photoelectric switch is applied for work-piece material level confirmation, cylinder lifting-declining mechanism or motor-driven lifting-declining mechanism is applied for furnace door lifting-declining, cylinder forced compaction structure is applied for solution furnace exit door, quenching sink adopts the heat-resistant stainless steel welded structure. The mixer is applied for water temperature mixing so that the water mixes well.

Solution furnace, aging furnace, quenching tank stand in a line or are arranged in the shape of "U". |

| STRUCTURAL CHARACTERISTICS |

1)����、simple transmission mode, short production cycle, low cost for equipment manufacture����;

2)�、convenient for Operation and maintenance ���;

3)、products loading:with charging basket�;It is the top priority for choice by the factories in the wheel manufacturing industry for aluminum alloy wheel heat treatment mass production. |