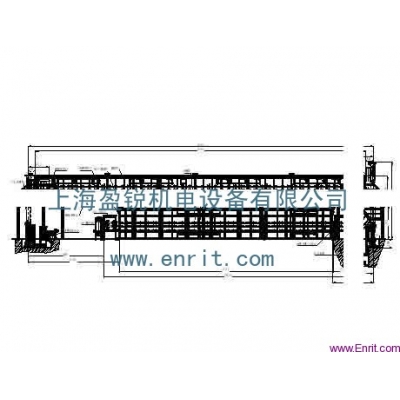

T-6 process continuous roller hearth technology vehicles aluminum wheel heat treatment furnace

Use

Aluminum alloy wheels for the automotive solution heat treatment, quenching, aging continuous treatment.

Structure description

Tapped by hot air circulation heating method, refractory materials and imports of cotton insulation board insulation, solid waste discharged directly into the furnace aging furnace, the motor drive gear driven operation mode for the sprocket, chain, drive gears, worm continuous operation, the heating components to the burner (the fuel for natural gas or liquefied gas) confirmed the use of radio material level photoelectric switch, solid furnace door upward and downward from the body with the top lift, aging furnace door liter motor lifting mechanism will be used. Solid melting pot of imports and exports by weight pressed door structure, quenching tank is heat welded stainless steel structure.

Solid furnace, aging furnace is located in the top of the steel platform.

Structural features

Compact structure, small size;

Low energy consumption; maintenance;

Transmission running smoothly;

Products directly over the drive roller, no shelter in the process, temperature uniformity of better cross-section; easily deformed, hub disposed of without any plastic surgery;

Quench tank, the water temperature mixing, several short-range movements by the action lifts to stir the water temperature, no mixer;

Furnace can handle different sizes of wheels;

High degree of automation can be unattended;

Automotive wheel manufacturing industry dealing with high quality requirements of the preferred heat treatment equipment manufacturers to mass production.