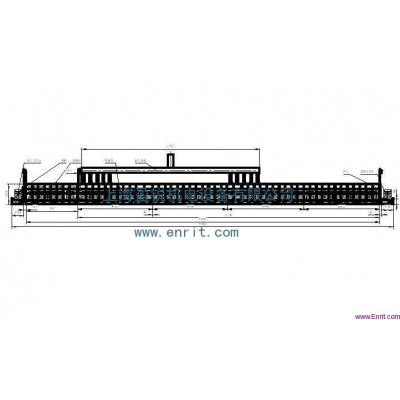

Alkali feldspar roaster

Alkali feldspar roaster Uses: Heat Treatment - Alkali feldspar material mixture Structure description: This equipment is fully automatic gas heat transfer continuous roller furnace, mainly by the import and export table, furnace, oven door and the door lifting mechanism, the heating zone, cooling zone, emission systems, roller conveyor system, the combustion system, electric control system, etc. Features: 1, the equipment is Alkali feldspar continuous roasting, cooling, baked whole process of automated control of the processing equipment; 2, the device size of the heating system uses natural gas, fire control pulse burner, multi-volume, low-power, furnace both sides of the staggered structure. Furnace temperature uniformity is better; 3, Alkali feldspar installed in the sagger in the layered material box installed in the grille plate, drive means for the clearance of the bottom roller gear type variable frequency motor drive, transmission run smooth, level recognition accuracy, speed adjustable running time interval can be adjusted by process requirements; 4, the cooling equipment products plus natural cooling method using air cooling, product cooling process time required to meet the low cost, 5, the device's door rising, falling, use of electric drive unit, drive safe and smooth; 6, the equipment design, compact structure, reasonable layout, nice shape. Control the high degree of automation, simple operation convenience.

- use: Heat Treatment - Alkali feldspar material mixture